Norwegian Olvondo with international breakthrough

Norwegian Olvondo with international breakthrough – enters into collaboration with Dutch multinational dairy company

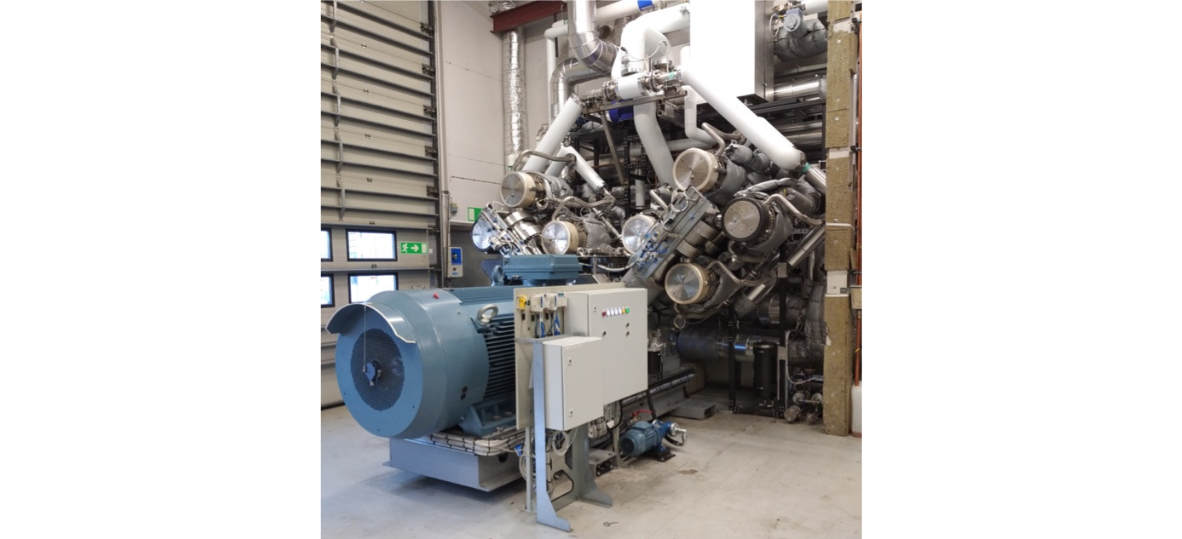

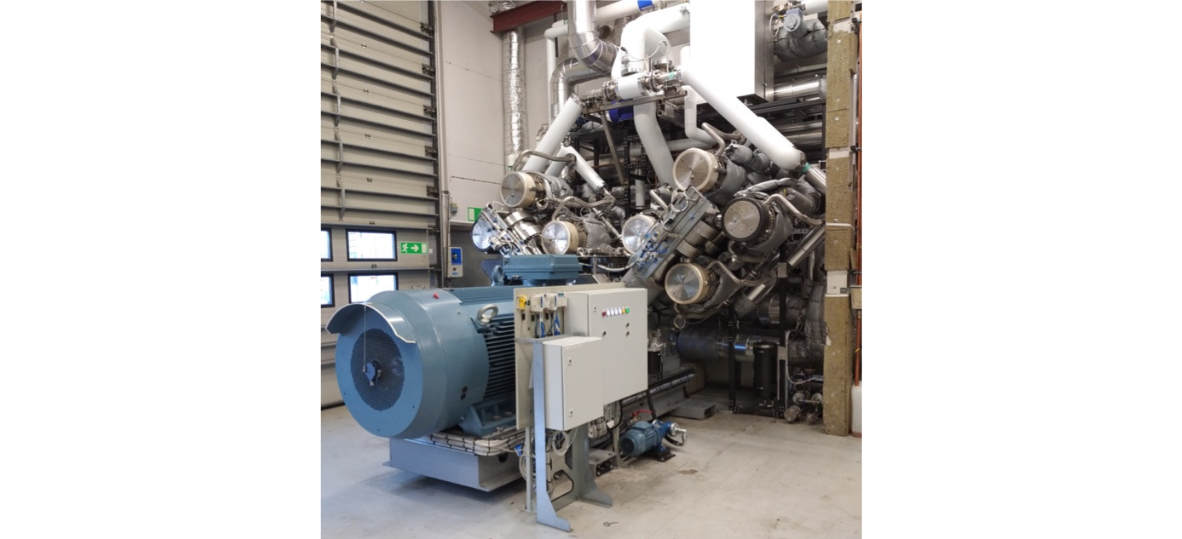

Olvondo Technology has developed a unique heat pump technology that helps to cut greenhouse gas emissions and energy costs. The company is now installing an innovative heat pump in one of the factories of Royal FrieslandCampina, a Dutch multinational dairy company owned by a dairy farmer cooperative, to pilot its latest generation of the HighLift heat pump.

“The agreement with FrieslandCampina is a great recognition of our technology, which we have been working for several years to develop. Together with FrieslandCampina, we have a project to demonstrate de-carbonization of process heat in dairies using steam generating heat pumps. The project is part of the Research Council of Norway’s regional implementation project and is part of the solution to the climate crisis,” says Stefano Vittor, CEO of Olvondo Technology.

Dairy company FrieslandCampina employs more than 20,000 people around the globe and has a strong presence in European, Asian and sub-Saharan African markets, in addition to the Americas. The company operates in both consumer goods and B2B markets, where products range from infant nutrition, to cheese, fresh dairy and ingredients for the pharmaceutical industry.

- Olvondo entered a collaboration with FrieslandCampina to pilot its latest generation of the HighLift heat pump. The selected site is in Maasdam, a factory producing fresh dairy, such as yoghurts, drinks, quarks, and custards. The building is now ready and installation of the heat pump has started. “This novel heat pump fits very well in the utility set-up of our factory, using waste heat as a primary source.” says Peter Huisman, Program Manager at FrieslandCampina. The HighLift Heat pump technology plays a key role in Maasdam, allowing it to significantly increase production volumes whilst reducing both energy usage and CO2 emissions with approximately 25%. The aim is to be fully operational early 2024, both parties are eagerly awaiting the results. “Heat pumps are a key element of FrieslandCampina’s decarbonisation efforts. We have been working with Olvondo for a while now and are impressed by the broad temperature ranges in which this technology can operate. This technology thus fits perfectly in our strategy to reduce greenhouse gas emissions in our production process and to avert rising energy costs. FrieslandCampina has set a target of 63% reduction in greenhouse gas emissions by 2030 compared to 2015 in production and milk transport.”, says Gerrit Westhoff, Global Supply Chain Sustainability Director at Friesland Campina.

Åbo Academy in Finland is supporting the project through developing a methodology for assessment and documentation of environmental impact from de-carbonization from industry processes using heat pumps.

The HighLift by Olvondo heat pump is one of the first steam generating heat pumps now commercially available in the market. The technology is gaining interest from companies world-wide. Pioneers like FrieslandCampina, focusing on innovation, deserves their credit for going in the forefront by deploying new technologies in order to reduce carbon emissions, concludes Vittor.